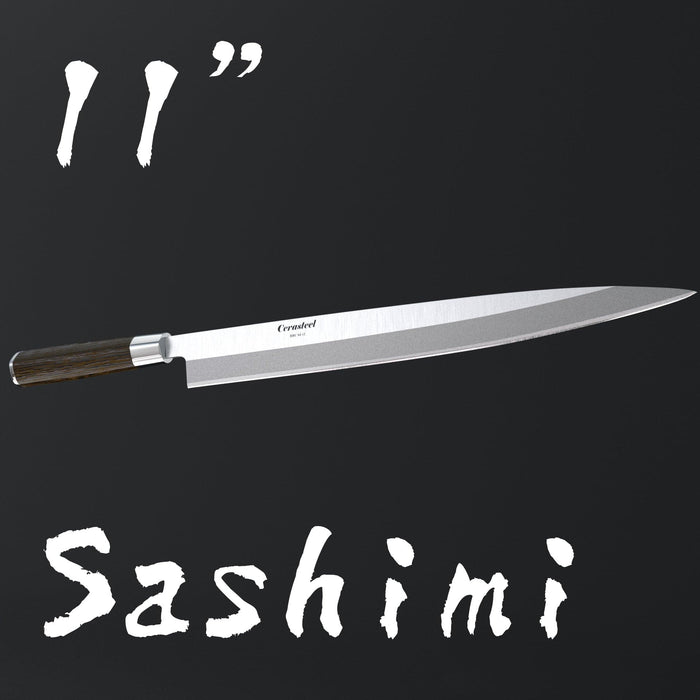

Sashimi Knife 11" Cerasteel

- Wear resistance is more than 100 times that of ordinary steel knives

- Hardness: HRC 64 ±2

- G10 fiber glass handle

Cerasteel material is an alloy which is combined by cement powder and steel together under a high temperature process. It is a high technology material which is used in aviation, aerospace and arsenals field, vehicle, oil exploration and nuclear power. The cutting edge of the cerasteel blade is welded by cement alloy powder, which is an excellent material for kitchen knife.

The cutting edge is lifetime guaranteed.

Using cladding technology in kitchen knives, is a revolution for knife making. Adding the cerasteel to the edge can substantially increase hardness, abrasion resistance, heat resistance and corrosion resistance.

The tenacity and shock resistance of Cerasteel is the same as a steel knife, thus its blade is not easily to make chips as ceramic knife.

Cutting surfaces should be smooth, easy to clean, such as wooden, bamboo and polyethylene boards.

Avoid surfaces that can damage the blade, such as ceramic, stainless steel, granite, marble, porcelain and glass.

BONUS

- Buy 2 Knives and get a BONUS Icon Chef Universal White Knife Block (Valued at $39)

- Buy 3 knives and get a BONUS FlexiBlock (Valued at $49)

Description

- Cerasteel is a NEW generation of materials for kitchen knives

- Wear resistance is more than 100 times that of ordinary steel knives

- Hardness: HRC 64 ±2

- G10 fiber glass handle

Cerasteel material is an alloy which is combined by cement powder and steel together under a high temperature process. It is a high technology material which is used in aviation, aerospace and arsenals field, vehicle, oil exploration and nuclear power. The cutting edge of the cerasteel blade is welded by cement alloy powder, which is an excellent material for kitchen knife.

The cutting edge is lifetime guaranteed.

Using cladding technology in kitchen knives, is a revolution for knife making. Adding the cerasteel to the edge can substantially increase hardness, abrasion resistance, heat resistance and corrosion resistance.

The tenacity and shock resistance of Cerasteel is the same as a steel knife, thus its blade is not easily to make chips as ceramic knife.

Cutting surfaces should be smooth, easy to clean, such as wooden, bamboo and polyethylene boards.

Avoid surfaces that can damage the blade, such as ceramic, stainless steel, granite, marble, porcelain and glass.